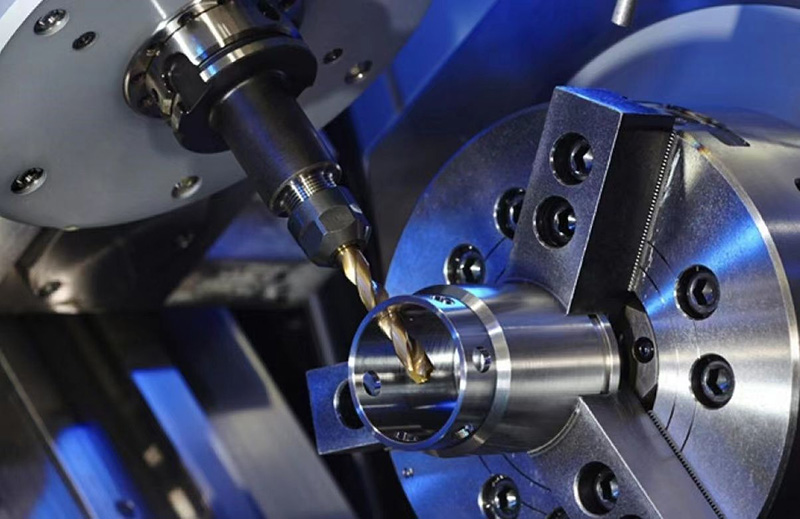

In CNC machining, precision is everything. However, even experienced machinists face challenges such as tool collisions, excessive cutting, and inefficient tool paths. Here are a few practical solutions to avoid some of the most common CNC programming issues:

1. Tool Collision :

This happens when the cutting tool impacts the workpiece with more than just the cutting edge, often due to improper safety height settings or an excessive cut depth. To prevent this:

Reduce the depth of cut, especially in roughing operations.

Modify cutting strategies (e.g., switch from contour milling to cavity milling when excess stock is present).

Ensure safety height is higher than the clamping fixture, particularly in complex setups.

2. Excessive Cut Depth:

When the stock left for secondary roughing is smaller than the previous roughing pass, it can cause tool deflection or collisions. A small tweak—like increasing the stock left by 0.05mm—can make a significant difference in maintaining tool integrity.

3. Safety Height & Toolpath Optimization:

Always avoid direct tool entry into the material and ensure tool paths are smooth and optimized. Too many tool retractions or excessive tool paths can lead to inefficiencies and errors.

Careful programming not only ensures precision but also extends the life of your tools and machines. A small change in strategy can save time, money, and materials in the long run.