CNC Machining & Precision Prototyping Supplier China | JLYPT

- High precision

- Complex geometries

- On-demand production

Step1

Upload the file.

Submit important details about your project

Step2

Receive DFM Analysis

We'll optimize the DFM for manufacturing analysis and provide price breakdown

Step3

Order Confirmation

Our engineer will confirm the order and begin production with the right process and materials.

Step 4

Receive Your Parts

Your parts will be delivered to your door directly with stringent deadlines. Get a Quote

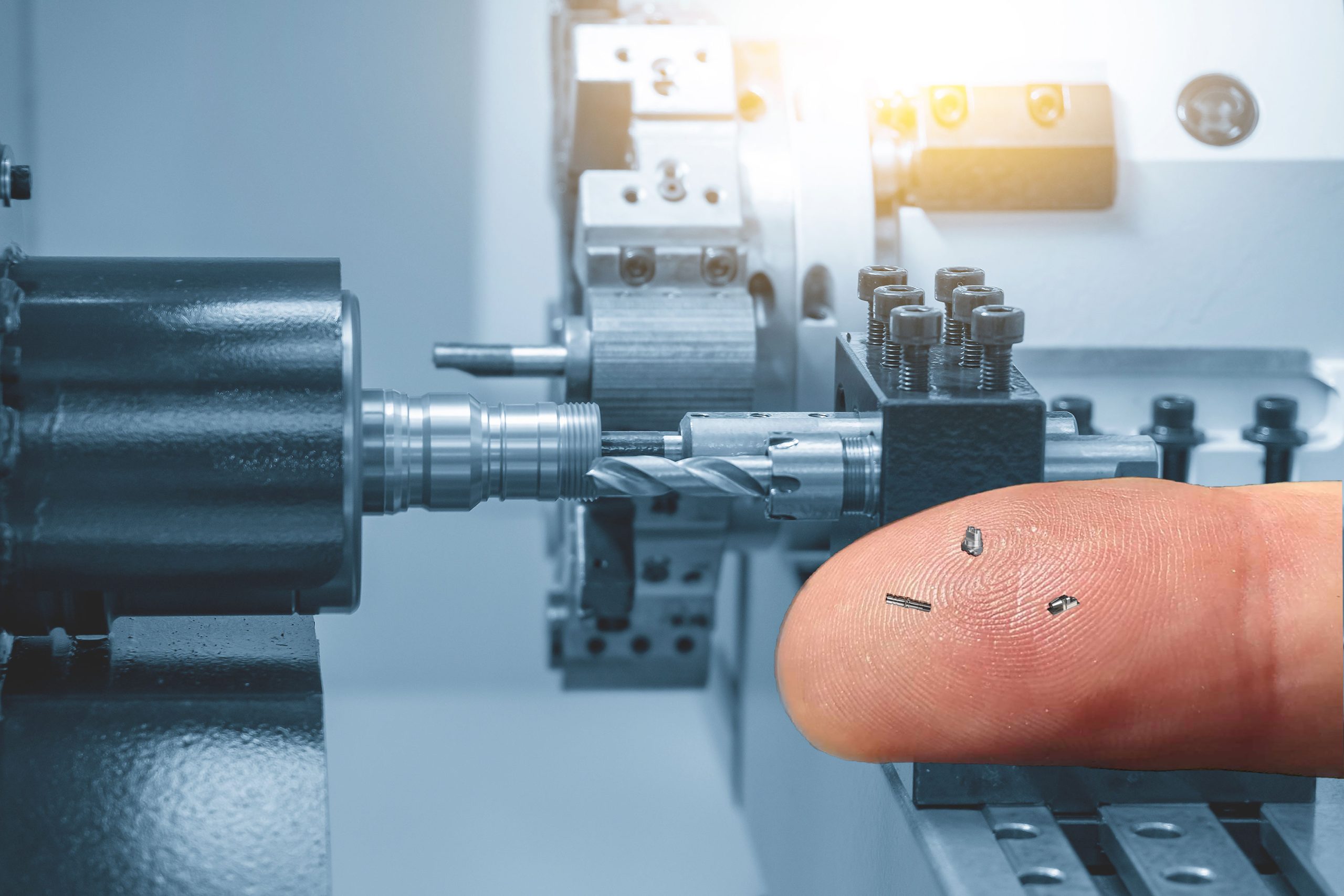

Crafting Engineering Solutions for Intricate Geometries

Whether you’re verifying a design with a prototype or looking for mass manufacturing solutions, JLYPT got you cover.

Our Manufacturing Capabilities

JLY Precision Technology specializes in delivering top-quality prototyping, as well as low and high-volume manufacturing solutions to meet your product development needs. Our global team collaborates closely with you to bring your ideas to life using advanced CNC technology, ensuring precise, reliable, and on-time delivery for every project.

When it comes to finding the right machining partner in China, we’re here to support you every step of the way!

100+ Materials Can Be Freely Selected

Metals

Choose the perfect material for your project’s success by exploring its distinct properties and benefits.

Durable, highly conductive, corrosion-resistant, with excellent machinability and thermal properties

Corrosion-resistant, durable, non-reactive, commonly used in industrial applications

Light, durable, oxidation-resistant, with excellent versatility across industries

Heat-resistant, corrosion-resistant, high-strength, ideal for extreme environments

Corrosion-resistant, highly durable, heat-tolerant, designed for harsh chemical environments

Corrosion-resistant, strong, highly durable, ideal for marine and chemical environments

Lightweight, exceptionally strong, corrosion-resistant, ideal for high-performance applications

High-strength, heat-resistant, chemically resistant, ideal for demanding engineering applications

Corrosion-resistant, durable, heat-tolerant, widely used in marine and industrial applications

Strong, lightweight, abrasion-resistant, with excellent flexibility and chemical resistance

What sets us apart

Choose us for expert solutions to complex machining challenges, precision engineering, and competitive pricing—delivered with reliability and speed.

In House Machining Process

Ensuring precision and quality with complete control over every step of production, from design to final component.

Streamline Vendors and Reduce Cost

Simplify your supply chain with integrated solutions for greater efficiency and cost savings

No MOQ Required

Enjoy flexibility with no minimum order quantities, allowing you to order exactly what you need, when you need it.

Meticulous Quality Control

Ensuring every component meets the highest standards through rigorous inspection and precision testing

Industry

We serve diverse industries with high precision demands, backed by a professional engineering team and advanced in-house equipment, delivering tailored machining solutions for complex challenges.”

Case Study

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.